OUR SOLUTIONS FOR VACUUM BOX LEAK TESTING (NDT LT)

Flying Vision designs high-performance vacuum box equipment for leak testing of welded joints in NDT and industrial inspection applications.

Our systems are rugged, portable, and engineered to comply with major international standards such as API 650, ASTM E515, EN 1593, as well as maritime-specific regulations including IACS UR S14, Lloyd’s Register Rules, and ABS Steel Vessel Guidelines.

Our complete range of vacuum boxes and dry vacuum pumps is perfectly suited for bubble leak testing of flat, curved, or complex weld seams, and is trusted across oil & gas, shipbuilding, tank manufacturing, and pipeline construction.

Discover reliable, field-ready, and efficient vacuum box testing solutions designed for professionals in quality control and non-destructive testing environments.

Our product

Vacuum Box

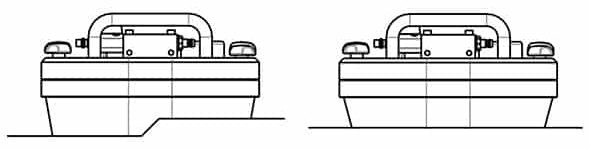

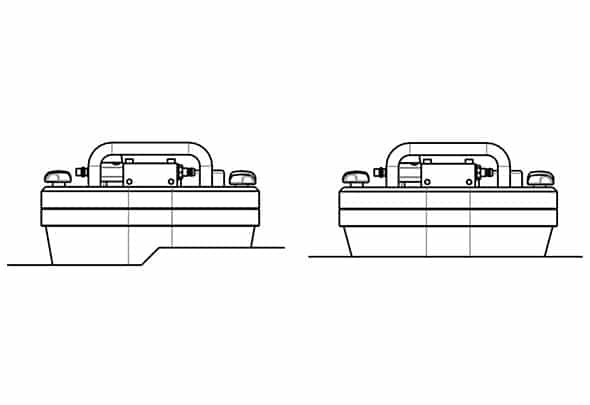

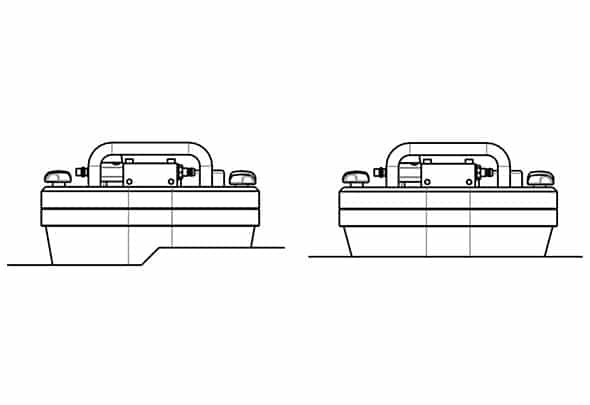

VACUUM BOX BAV-7025

Ref : BAV-A100-001

CONTROL CONFIGURATION

Vacuum box designed for leak testing on:

- Flat welds

- Lap joints, lap welds

- Internal or external circular welds depending on the curvature radius

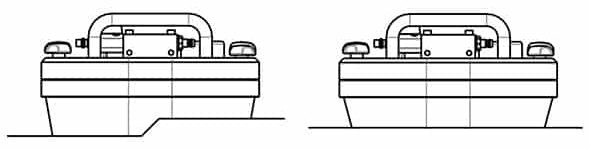

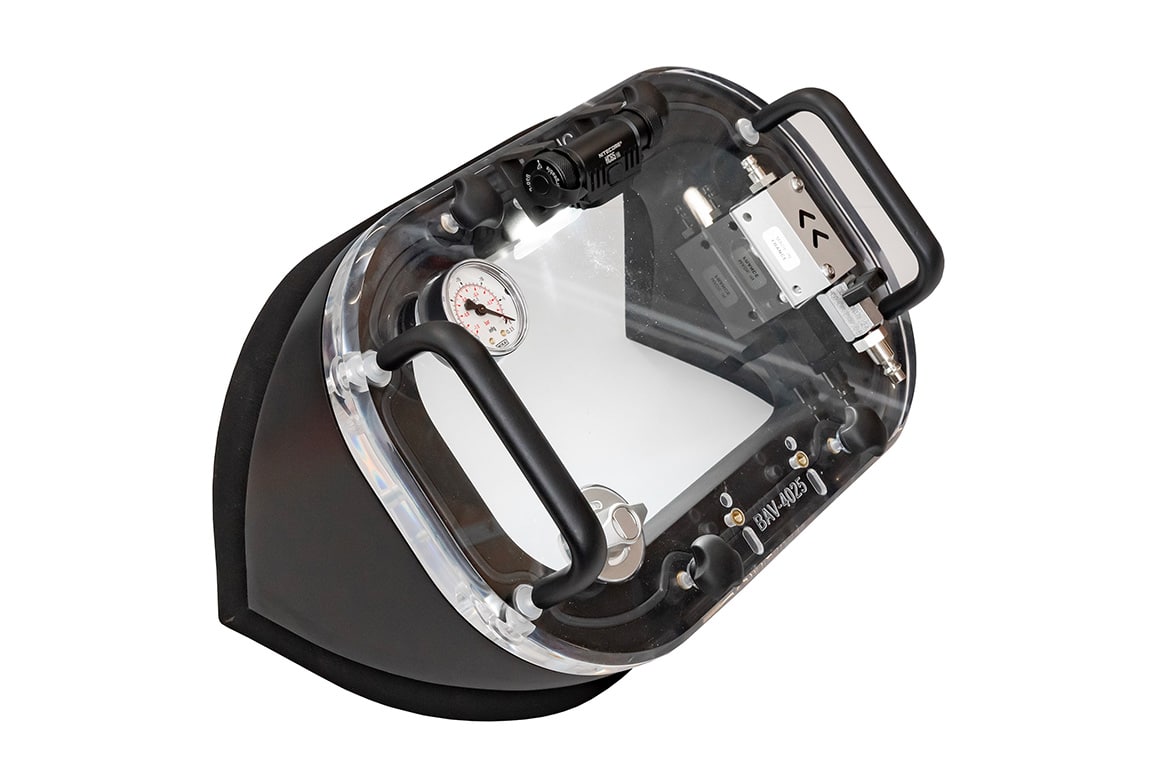

VACUUM BOX BAV-4025

Ref : BAV-A200-001

CONTROL CONFIGURATION

Vacuum box designed for leak testing on:

- Flat welds

- Lap joints, lap welds

- Internal or external circular welds depending on the curvature radius

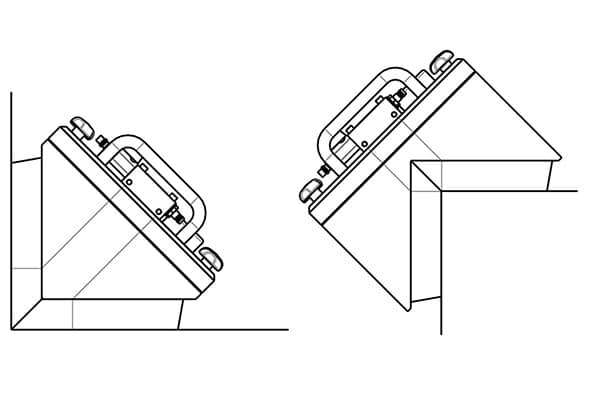

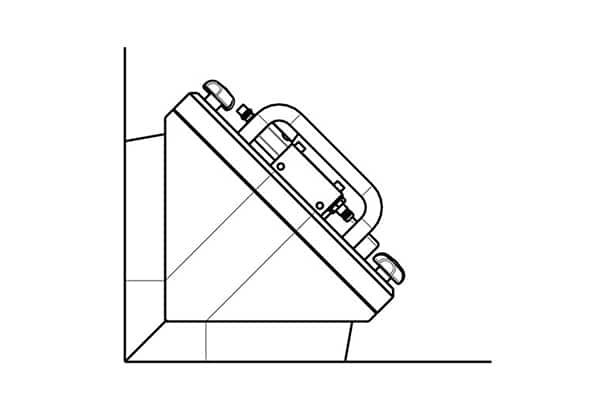

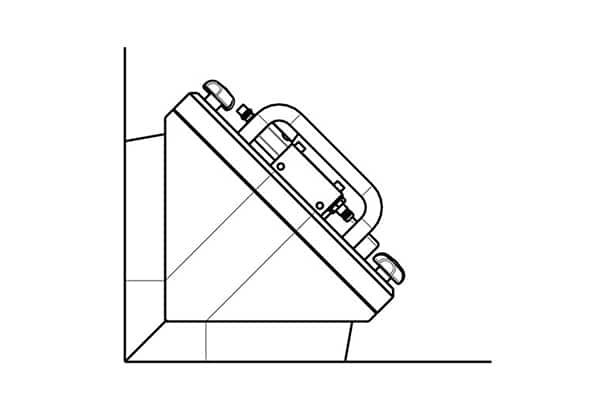

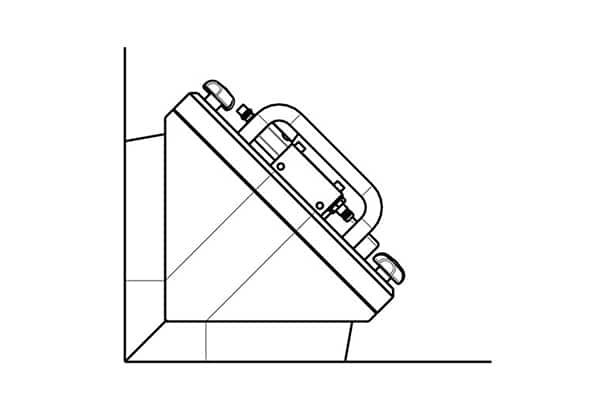

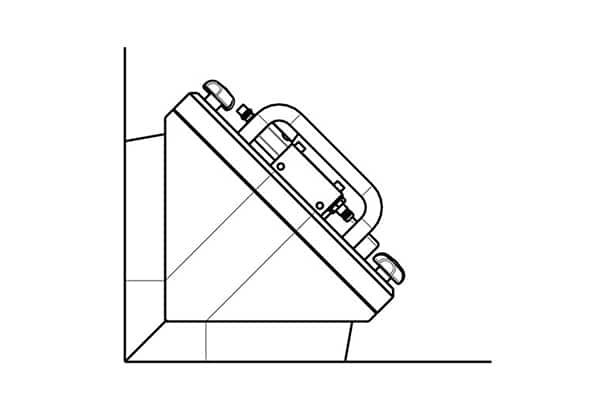

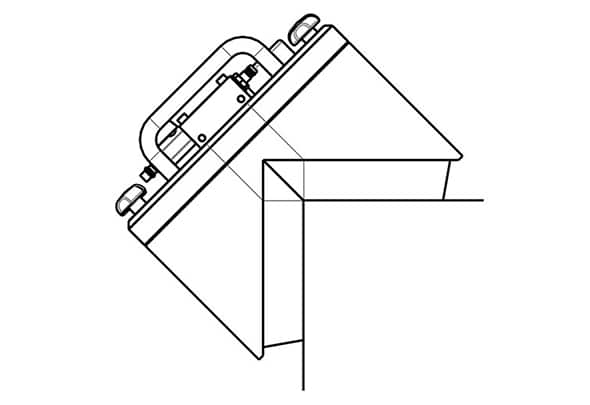

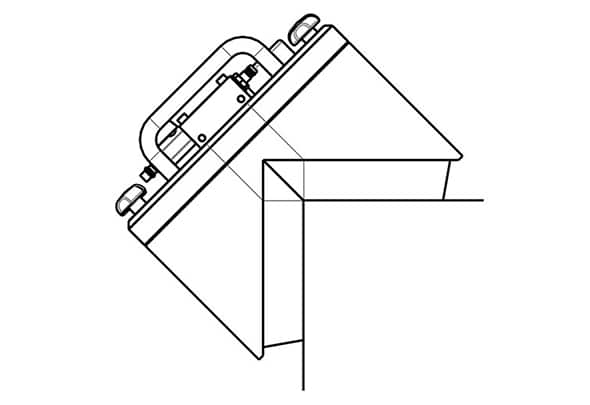

VACUUM BOX BAV-4025A SERIES

Ref : BAV-A300-x

CONTROL CONFIGURATION

Series of vacuum box designed for leak testing on:

- Internal angle welds

- External angle welds

- Internal or external angle welds with a varying angle

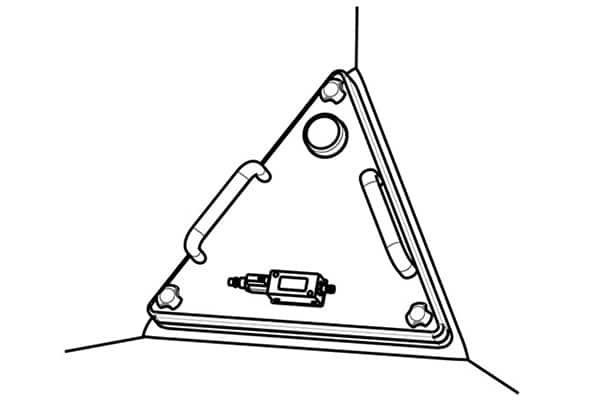

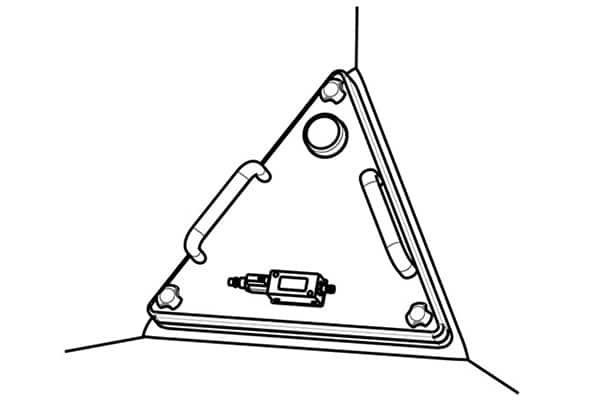

VACUUM BOX BAV-40C

Ref : BAV-A400-001

CONTROL CONFIGURATION

Series of vacuum boxes designed for leak testing on:

- Internal corner welds at 90°

- Internal corner welds where an isosceles plane is

- Present

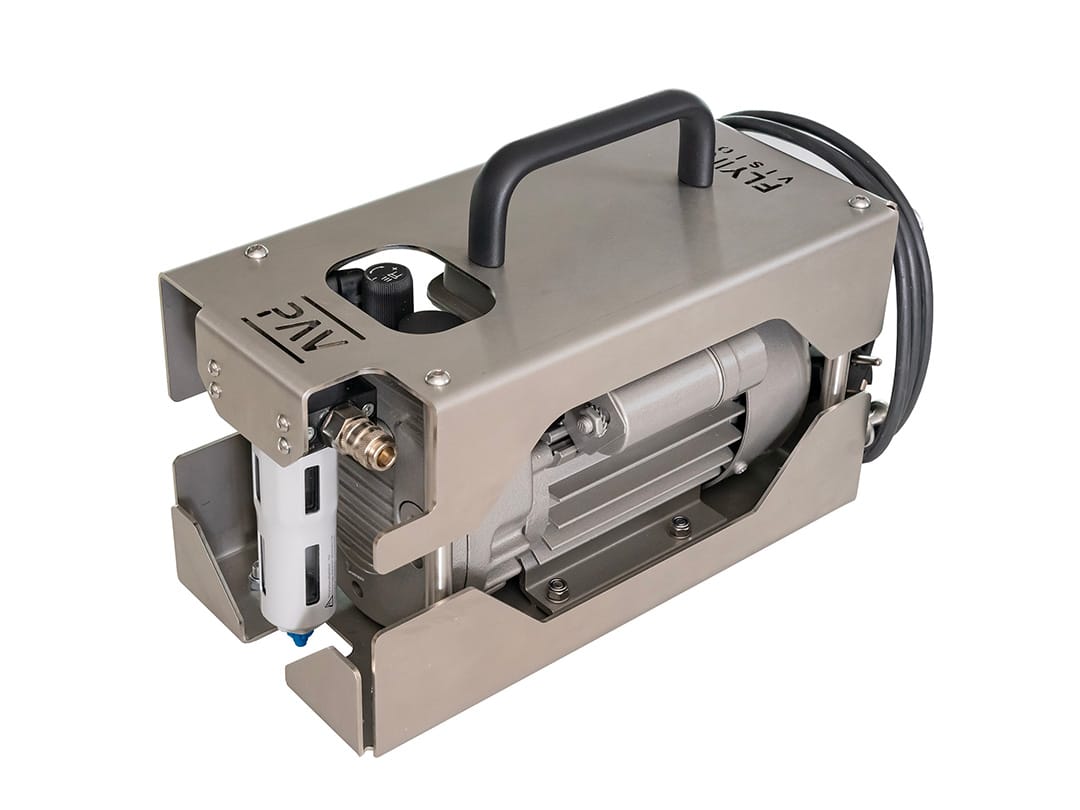

Vacuum Pump

VACUUM PUMP

Ref : PAV-B8-xxx

110/120V or 220/240V Dry vacuum pump

8 m³/h – 150mbar vacuum – Dry vacuum pump designed for most demanding field conditions.

It is the ideal solution for generating vacuum during your vacuum box leak testing operations.

Options and Accessories

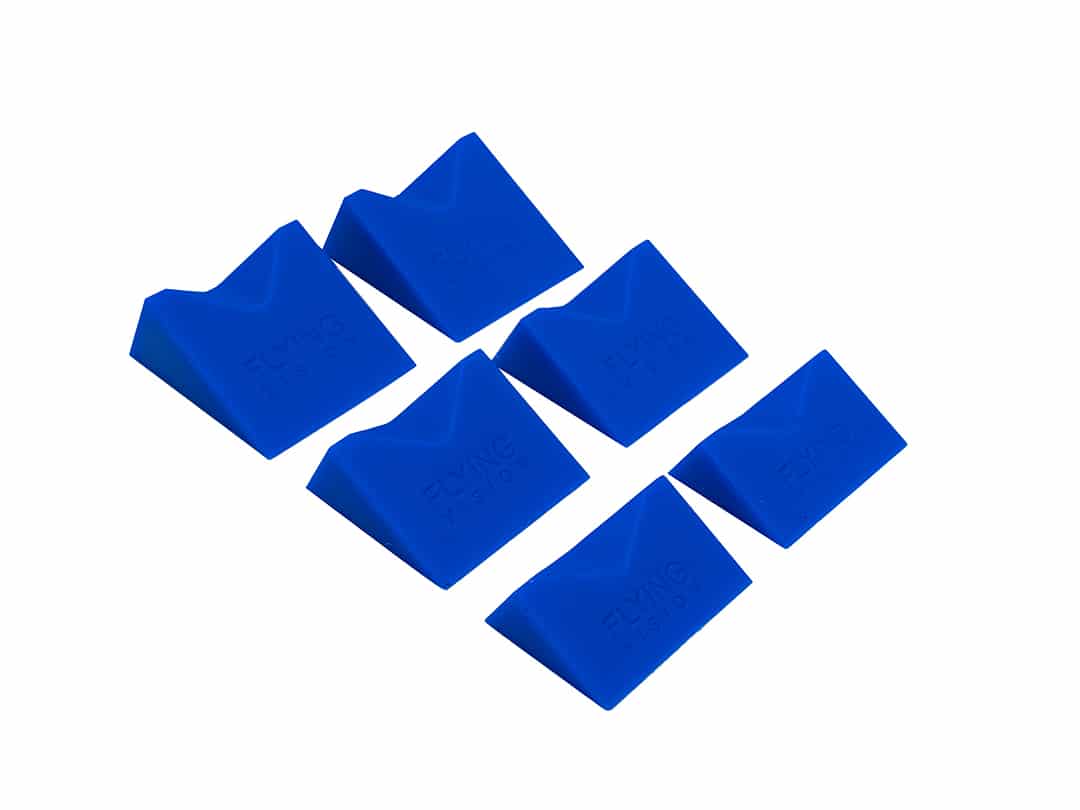

SILICONE SPACERS KIT

Ref : BAV-090

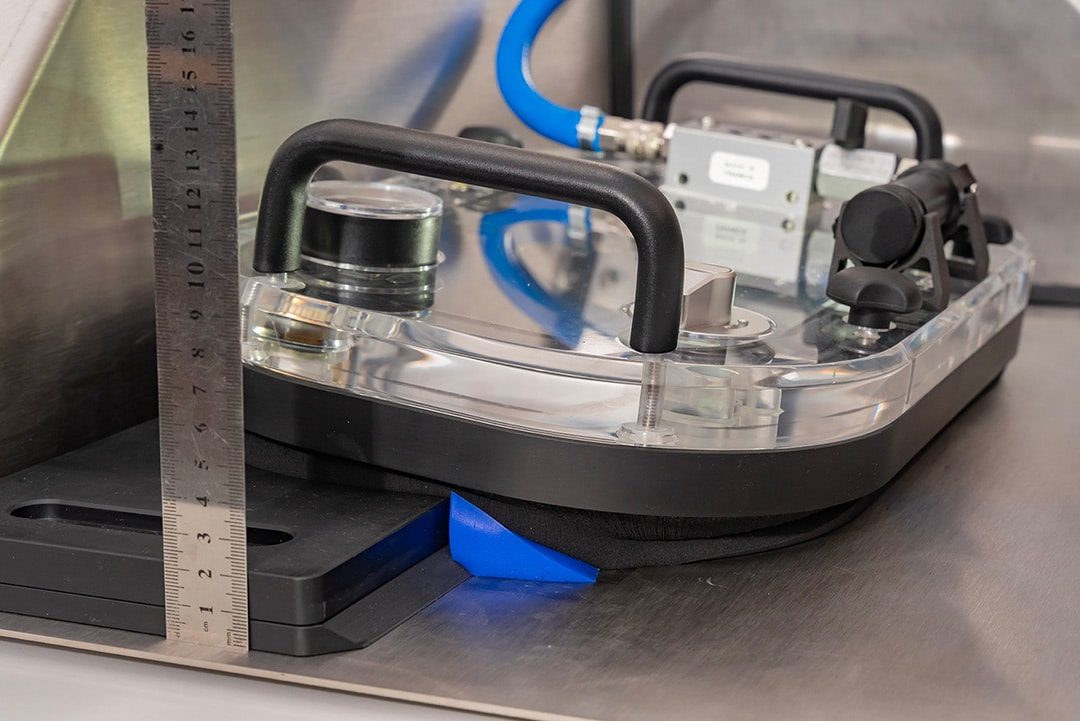

For vacuum box inspections of lapwelds

Innovative solution to perform vacuum box leak testing on lap weld joints up to 25 mm, depending on the vacuum box model selected.

LED LIGHTING

Ref : BAV-A050

Led lighting option for all BAV vacuum box series

Removable, battery-powered LED lighting system designed for all BAV vacuum box series.

This accessory makes it easy to achieve the minimum required lighting level during your vacuum box leak inspections.

VACUUM PUMP HOSES

Hoses for the PAV-B8 series vacuum pumps

Extension hoses equipped with Rectus 21 male and female quick couplings, for connecting any BAV series vacuum box to your PAV-B8-XXX vacuum pump.

Vacuum box for Leak Testing

Operating principle

Vacuum box testing is a non-destructive testing (NDT) method used to check the seal integrity of welded joints. This process utilizes a vacuum box, often made of Plexiglas, in conjunction with a vacuum system to create a pressure differential. A reactive agent, which generates bubbles, is applied to the surface under test.

Purpose of the bubble leak test

The main goal of this bubble leak testing method or vacuum box inspection is to identify leaks in systems that cannot be conventionally pressurized. In the event of a leak, the reactive agent creates bubbles, providing a visual indication of the leak.

Therefore, it is essential to maintain a clear reading of indications that the distance between the vacuum box’s window and the inspected surface be at least 1 to 2 cm.

Areas of application

- Vacuum box test for tanks / Storage tanks (vacuum box testing tank bottom or shell)

- Ship hulls

- Overlap, butt welds (vacuum box weld testing equipment)

- Roofing waterproofing sheets and membranes for flat or terrace roofs

- Any other surfaces (metallic or not) where a pressure gradient can be applied

Main Features of our Vacuum Box

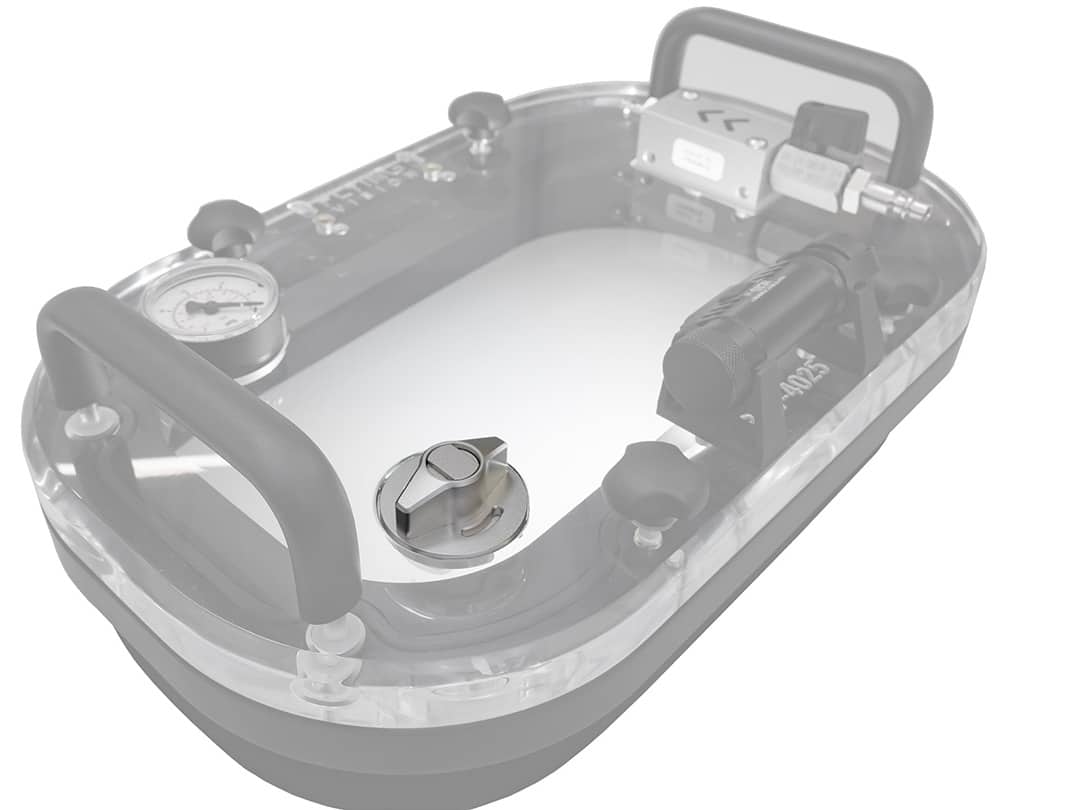

TWO PARTS MODULAR DESIGN

- Independent inspection window including all elements necessary for inspection processing (vacuum gauge, hybrid vacuum system, and handling grips)

- Height of the inspection chamber at least 2cm to facilitate indication interpretation

- Interchangeable base for:

- Quick maintenance

- Modularity / configuration change

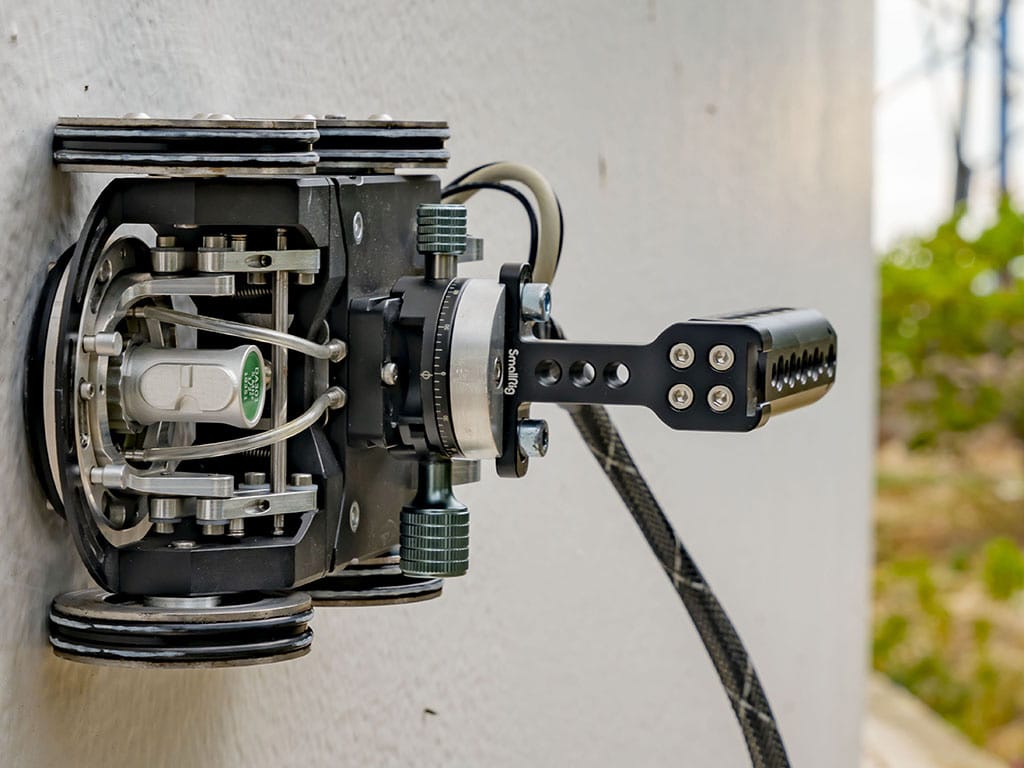

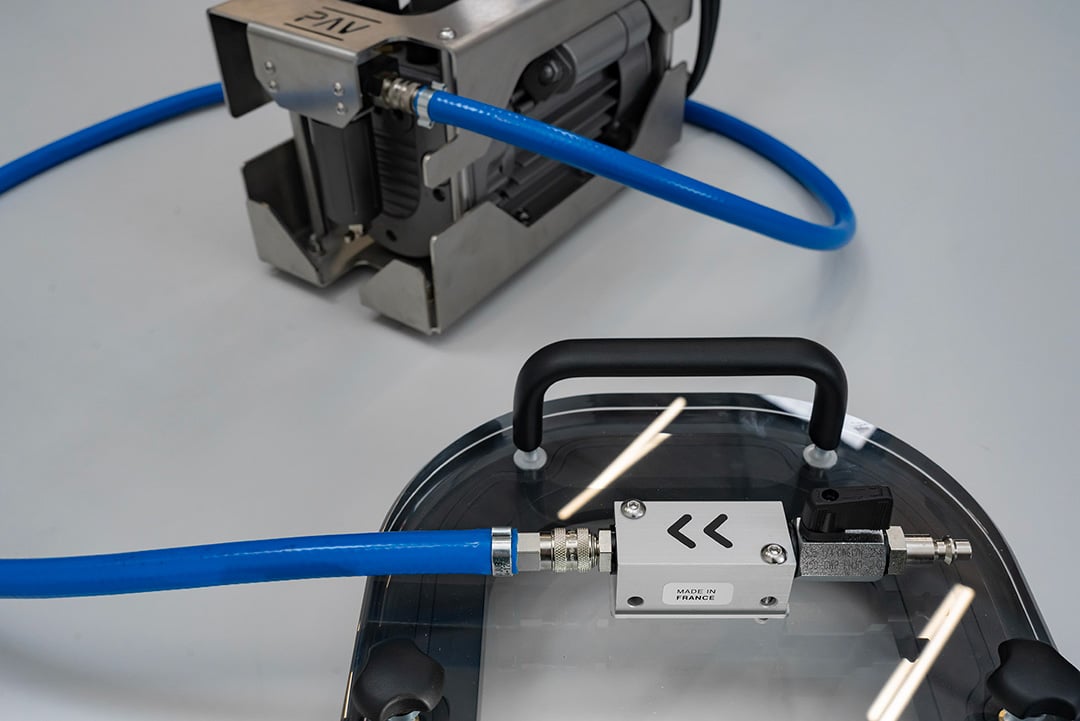

HYBRID VACUUM SYSTEM

- Aluminum and stainless steel design for enhanced durability

- Integrated into the window to ensure mechanical protection

- Venturi effect vacuum

- Airflow regulation valve on the Venturi side

- Quick coupling Rectus type 23 male

- Vacuum pump suction

- Aluminium control valve

- Quick coupling Rectus type 21 male

CONTROL VALVE

Our vacuum boxes include an anodized aluminum quick-control valve system performing the following functions:

- Quick adjustment of the vacuum pressure using either the Venturi effect or a vacuum pump

- Release valve for eliminating the vacuum and immediately detaching the vacuum box

VACUUM ADJUSTMENT AND REGULATION

- Integrated vacuum gauge within the window for mechanical protection

- Easily removable with a single nut

- Measurement range: 0 to -1 bar

- Calibration certificate available as an option

- Flow regulation valve with venturi effect mode

- Can be used for fine vacuum adjustment when a vacuum pump is in use

HIGH PERFORMANCE FOAM

- High resistance to abrasion

- Flexibility 40/50 shore 00

- Standard foam heights of 35 mm

- High deformation and clearance capacity (around 20mm for standard foam and around 30 mm for 50 mm foam with silicone spacers option)

- Innovative geometry to ease application and reduce effort

- High resistance adhesive bonding

- Resistant to hydrocarbons and most chemicals

VIEWING WINDOW

With its two-part design, the vacuum box features a 15 to 20 mm high viewing window that allows for clear interpretation of readings during inspections.

LED LIGHTING (optional)

This option allows you to easily meet the minimum lighting requirements necessary for your vacuum box inspections.

- Removable LED lighting with battery

- USB-C charging port

- Diffuser to reduce reflections

- Light temperature 4500°K

- Adjustable from 500 to 15000 Lux

- 6 hours of battery life at 2500 Lux

- IP68 protection

Overview of our Vacuum Box Product Range

BAV7025 Series Kits

Reference / Designation

Réf: BAV-A100-001

BAV7025 – Flat vacuum box kit

Control Configuration

Specifications

Dimensions

700 x 250 x 130 mm

Weight

7.2 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Max Controllable Height

≈ 15 mm

Min Control Radius

≈ 8 m

BAV4025x Series Kits

Reference / Designation

Réf: BAV-A200-001 / 002*

BAV4025 – Flat vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 130 mm

Weight

4.5 kg

Foam Height

35 mm / 45 mm*

Foam Hardness

40/50 Shore 00

Max Controllable Height

≈ 15 mm /25 mm*

Min Control Radius

≈ 3 m / 2.5 m*

Reference / Designation

Réf: BAV-A300-2

BAV4025A – 70° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 300 mm

Weight

6.5 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

70°

Min Control Radius

≈ 65° à 80°

Reference / Designation

Réf: BAV-A300-1

BAV4025A – 90° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 250 mm

Weight

6.2 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

90°

Max Controllable Angle

≈ 80° à 100°

Reference / Designation

Réf: BAV-A300-3

BAV4025A – 110° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 220 mm

Weight

6 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

110°

Max Controllable Angle

≈ 100° à 120°

Reference / Designation

Réf: BAV-A300-4

BAV4025A – 130° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 190 mm

Weight

5.8 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

130°

Max Controllable Angle

≈ 120° à 140°

Reference / Designation

Réf: BAV-A300-5

BAV4025A – 220° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 190 mm

Weight

6.2 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

220°

Max Controllable Angle

≈ 210° à 230°

Reference / Designation

Réf: BAV-A300-6

BAV4025A – 270° angle vacuum box kit

Control Configuration

Specifications

Dimensions

400 x 250 x 190 mm

Weight

6.2 kg

Foam Height

35 mm

Foam Hardness

40/50 Shore 00

Nominal Control Angle

270°

Max Controllable Angle

≈ 260° à 280°

Optional Bases for the BAV4025x

Reference

Designation

Réf: BAV-A220-1

Complete base for BAV4025x – 180° Angle / flat base – Foam height 35mm

Réf: BAV-A220-2

Complete base for BAV4025x – 180° Angle / flat base – Foam height 50mm

Réf: BAV-A320-2

Complete base for BAV4025x – 70° Angle – Foam height 35mm

Réf: BAV-A320-1

Complete base for BAV4025x – 90° Angle – Foam height 35mm

Réf: BAV-A320-3

Complete base for BAV4025x – 110° Angle – Foam height 35mm

Réf: BAV-A320-4

Complete base for BAV4025x – 130° Angle – Foam height 35mm

Réf: BAV-A320-5

Complete base for BAV4025x – 220° Angle – Foam height 35mm

Réf: BAV-A320-6

Complete base for BAV4025x – 270° Angle – Foam height 35mm

BAV40C Kits series

Reference / Designation

Réf: BAV-A400-001

BAV40C – int. corner vacuum box kit

Control Configuration

Specifications

Dimensions

490 x 270 x 130 mm

Weight

4.5 kg

Foam Height

15 mm

Foam Hardness

40/50 Shore 00

Controllable Angle

Internal corner at 90° or

corner where the 3 sides

form an isoscel

FAQ / Frequently Asked Questions – Vacuum Box Leak Testing

Whether you’re new to vacuum box leak testing or seeking clarification on technical requirements, this FAQ section answers the most common and critical questions professionals ask.

From compliance standards to vacuum sources and lighting levels, we cover everything you need to inspect with confidence.

Vacuum Box Basic FAQ

What is vacuum box testing?

Vacuum box testing is a non-destructive testing (NDT) method used to detect leaks in weld seams and other critical joints by creating a vacuum over the test area and inspecting for air bubbles.

How does a vacuum box work?

A vacuum box works by creating a controlled vacuum over a section of the test surface, typically a weld, and using a bubble-forming solution to detect escaping air through any defects.

What are the benefits of vacuum box testing?

- Fast and reliable leak detection

- Cost-effective and easy to perform

- High sensitivity to small leaks

- Compliance with industry standards (API 650, ASTM E515, EN 1593)

Vacuum Box Technical FAQ

What is the correct vacuum box testing procedure?

Vacuum box testing consists of applying a bubble-forming leak detection solution to the weld surface, placing the vacuum box, pulling a defined negative pressure, and inspecting through a transparent window for air bubbles.

Standards such as API 650 and EN 1593 define minimum vacuum level, hold time (typically 10 seconds), and test coverage.

A minimum lighting level of 500 lux is recommended for reliable visual inspection, although 1,000 lux or more is preferred for dark surfaces or field use.

Can foam seals adapt to lap welds and complex geometries?

Yes. Our vacuum boxes are equipped with flexible or triangular foam seals that compress to conform to most surface shapes, including lap welds, curved weld seams, and internal corners.

For more difficult geometries — such as thick lap welds with significant offset — our BAV-090 silicone spacer kit improves seal contact and vacuum integrity, ensuring reliable leak detection even in challenging configurations.

What vacuum level is required to perform a compliant test?

Most international standards recommend a vacuum level between -200 and -300 mbar (gauge) for reliable leak detection, typically maintained for 10 seconds.

Standards like API 650 and EN 1593 follow this range. However, in industries like Oil & Gas or energy production, higher vacuum levels (e.g. up to -600 mbar) may be required depending on safety policies and inspection protocols.

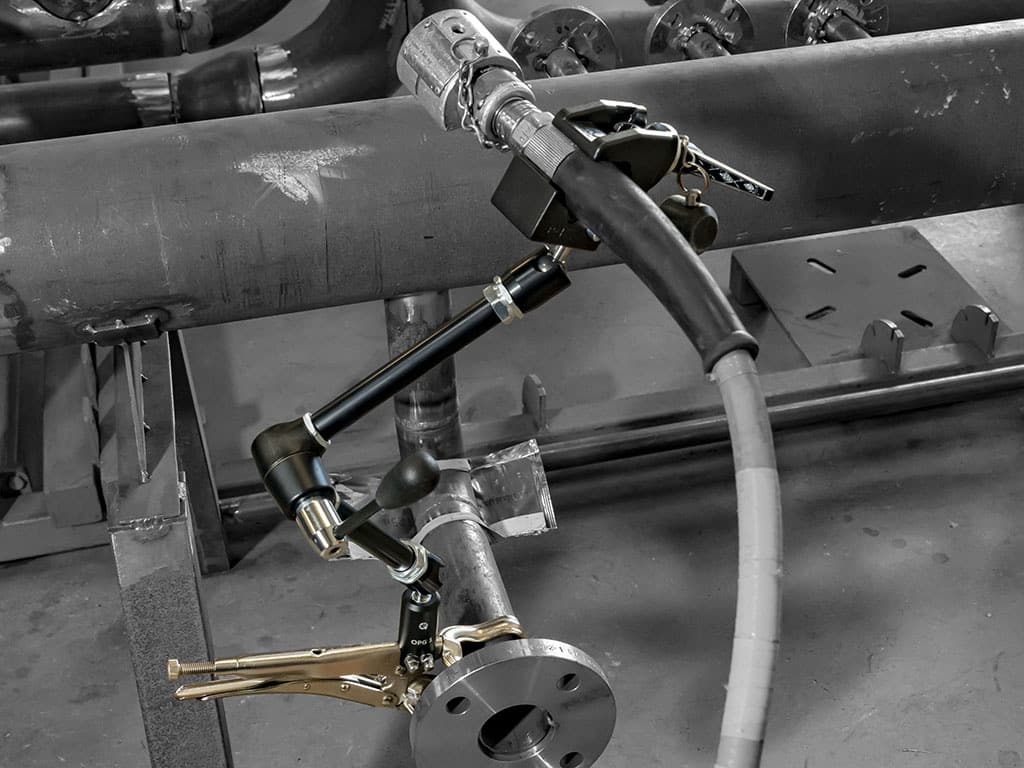

What type of vacuum pump should I choose for field testing?

For leak testing in field conditions, a dry rotary vane vacuum pump is recommended. Unlike oil-lubricated pumps, dry pumps are portable, maintenance-free, and safe to tilt or transport, with no risk of oil spills or failure due to improper positioning.

They offer sufficient vacuum for compliant inspection without exceeding pressure limits defined in NDT standards.

Can I use a compressor and Venturi system to generate vacuum?

Yes. All our vacuum boxes are equipped with a hybrid vacuum block that includes a built-in Venturi system, allowing vacuum to be generated using compressed air.

This is a practical solution on job sites where electricity is limited, but compressed air circuits or portable diesel compressors are available.

To operate the Venturi efficiently and reach up to -0.85 bar, we recommend a compressor with:

• Minimum air flow: 250 L/min (≈ 9 CFM)

• Working pressure: 7–8 bar

• Tank capacity: 25 to 50 liters

This hybrid setup also allows direct connection to a dry rotary vane vacuum pump when electric power is available.

What is the minimum lighting level for vacuum box inspection?

Proper lighting is essential for visually detecting bubbles during a vacuum box leak test.

Although most standards do not specify an exact value, general NDT guidelines such as EN 13018 recommend a minimum of 500 lux for visual inspections.

In practice, we recommend using at least 1,000 lux, especially in dark environments, to ensure clear visibility through the inspection window.

Our LED lighting system is designed to meet these conditions, with adjustable brightness from 500 to 15,000 lux.

Vacuum Box Standards FAQ

What international standards apply to vacuum box leak testing?

Vacuum box testing is recognized by multiple international standards.

It is mentioned in API 650, API 653, and API 620 for storage tank construction and inspection, as well as in ASME BPVC and EN 1593 for pressure equipment.

In the marine sector, it’s included in IACS UR S14, Lloyd’s Register, and ABS Rules. These standards define how vacuum box testing is applied to verify weld integrity in non-destructive testing.

What vacuum box testing standards apply in the maritime and shipbuilding industry?

Vacuum box testing is officially recognized in maritime construction and ship maintenance by several classification societies.

It is detailed in IACS UR S14, which outlines procedures for testing welded joints and watertight compartments using a vacuum box with transparent window and bubble-forming solution.

The method is also referenced in the rules of Lloyd’s Register and ABS (American Bureau of Shipping), particularly for bottom welds, lap joints, and storage tanks on vessels.

These standards typically require a vacuum level between -0.20 and -0.26 bar, with clear visual confirmation of leak absence during a controlled pressure hold.

How to perform a vacuum box test according to API 650?

To perform a vacuum box test according to API 650, ensure the test area is clean, maintain the surface temperature between 5°C (40°F) and 50°C (125°F), use a commercial leak detection solution, apply a vacuum of at least 0.55 bar (8 psi), verify the pressure with a calibrated gauge, and maintain the vacuum for a minimum of 10 seconds per test section. Adequate lighting of 1,000 lux is recommended for accurate visual inspection.